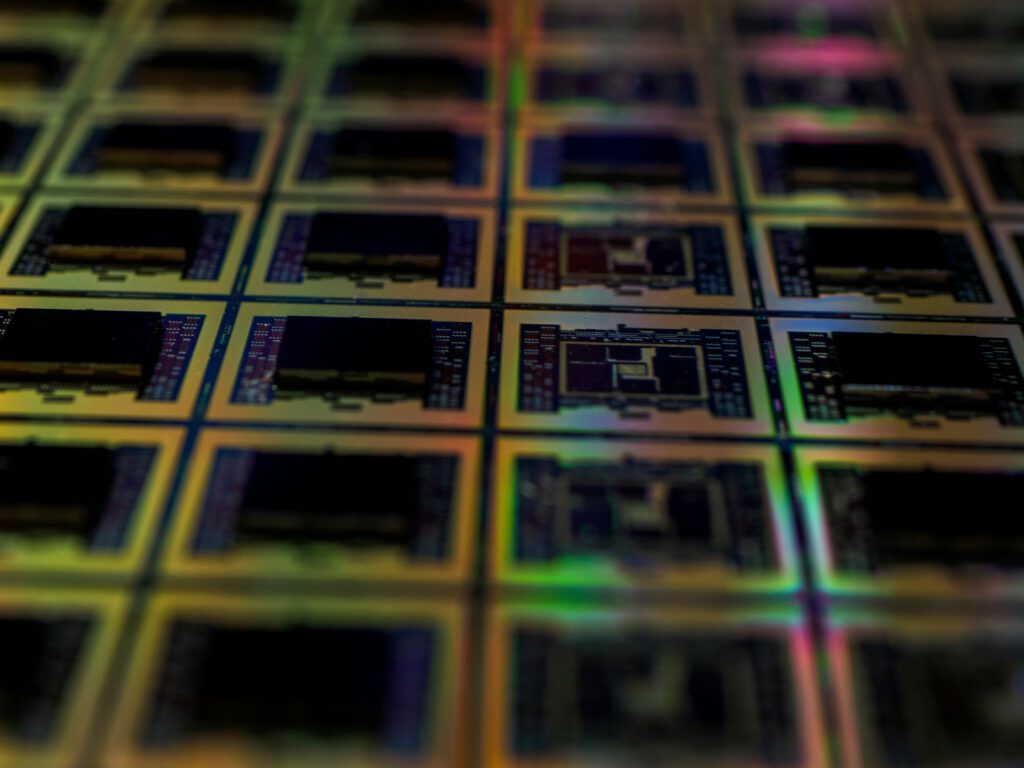

Precision Cleaning, Made in Germany

SONIQ blends high-frequency acoustic innovation with German engineering. Fully assembled in Germany, our system delivers unmatched uniformity in wafer cleaning while minimizing particle contamination and ensuring structural integrity – for use across high-precision applications.

Flawless cleaning from center to edge

Designed for the most demanding substrates

Built for durability and long-term reliability

SONIQ’s refined technology is deeply versatile. Whether you’re in semiconductors, optics, MEMS, or solar manufacturing, our system removes sub-micron particles easily and gently using high-frequency acoustic energy – without the need for harsh chemicals or aggressive cycles.

Semiconductor cleaning (front-end, post-CMP, photoresist removal)

Precision optics cleaning

MEMS and microstructure processing

Solar wafer particle removal

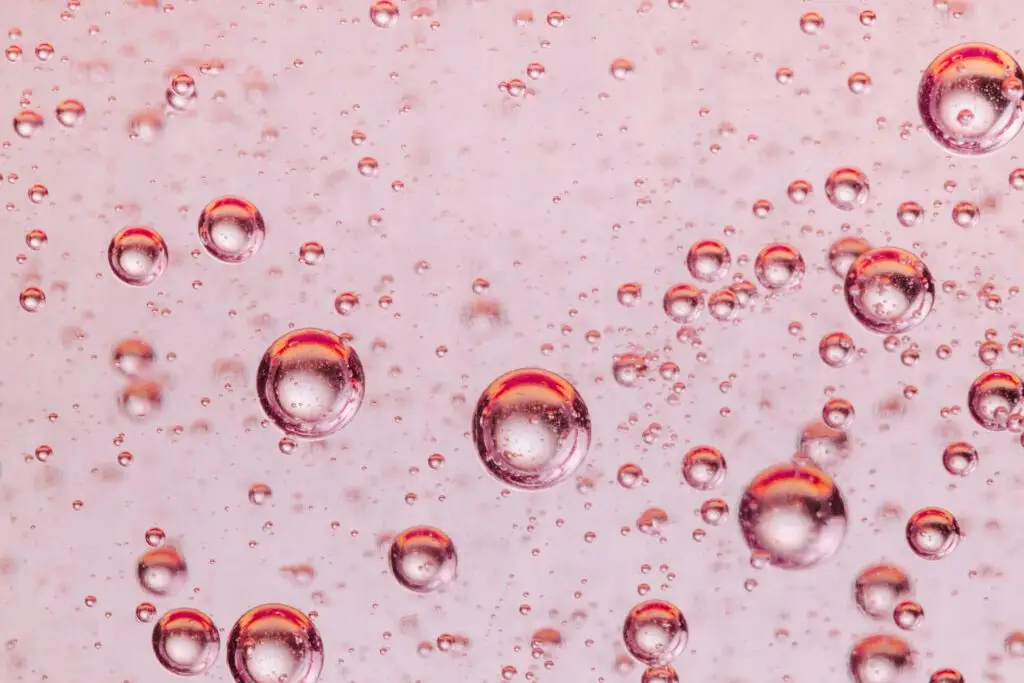

Delivers uniform megasonic energy from wafer center to edge, ensuring consistent removal of sub-micron particles without damaging delicate structures.

Designed, assembled, and quality-checked in Germany for exceptional reliability, long service life, and superior performance.

Ideal for semiconductor, MEMS, optics, and solar industries - adaptable to various chemistries and process environments.

Optimized for reduced process times, lower operating costs, and improved product yield through superior contamination control.

The SONIQ Megasonic System redefines precision cleaning. Whether you’re focused on removing sub-micron contaminants, accelerating cycle times, or ensuring system reliability, SONIQ brings German-engineered performance to your production floor. Explore its core advantages designed to enhance yield, efficiency, and uptime.

Consistent Acoustic Coverage

Engineered to deliver uniform megasonic energy across the wafer surface – from center to edge – ensuring reliable results every time.

Chemical Resilience & Adaptability

Built to endure a wide range of process chemistries, SONIQ offers flexible integration into diverse cleaning workflows.

Modular and Maintainable

With a service-first design, parts are easy to access and upgrade – minimizing downtime and maximizing longevity.

Reliable, German-Assembled Quality

Each unit is assembled and tested in Germany, giving you peace of mind with precision build quality and dependable performance.

From the first concept to the final test, SONIQ was built with one goal: to optimize your cleaning process. Leveraging advanced megasonic technology and robust German assembly, it delivers consistent, measurable improvements in throughput, yield, and cost efficiency – no matter your application.

High Particle Removal Efficiency

Removes even the smallest contaminants while protecting fragile structures and surface features.

Energy-Efficient Operation

Optimized acoustic power delivery reduces energy use while maintaining exceptional cleaning performance.

Flexible Integration

Designed to fit seamlessly into both new and existing cleaning tools, with minimal installation effort.

Proven Reliability in Production

Trusted by manufacturers for continuous operation in demanding, high-volume environments.